Information

Virtual product and process optimization for the future. For more than 25 years, HTCO GmbH has been an expert in modern and efficient engineering using flow simulation (CFD). HTCO takes a close look at fluidic processes in plants and technical products, identifies potential for increasing energy efficiency and implements effective engineering solutions to optimize them. In addition, HTCO is involved in various national and international research projects. Perfecting technologies in their form and function so that they become more energy-efficient, economical and environmentally friendly is HTCO's credo.

Energy efficient solutions and innovations without detours. Through precise numerical flow calculations, to-the-point analyses and innovative approaches to solutions, we shorten your engineering processes and get you directly to your goal. Thanks to our many years of experience, we are able to use CFD flow simulation in such a way that physical relationships become visible and calculable in the design phase in a fast way, which can otherwise only be experienced through lengthy trials or prototype series. From this solid physical basis, we develop creative ideas on how products or processes can be designed to be more flow-friendly and thus more efficient in the long term.

Services

CFD Engineering

Efficient engineering solutions through in-depth CFD know-how

As a service provider for CFD engineering, we make targeted use of CFD flow simulation (computational fluid dynamics) to make physical relationships visible that lead to inefficiency or even malfunction of products or processes. Already in the design phase, we simulate the processes in possible design options under the influence of various material and application parameters and develop well-founded optimization approaches for the best possible function and lowest energy and material consumption. When very time-critical and cost-intensive cases of damage, functional errors or process problems occur, we simulate the processes in the product or process in order to quickly uncover the causes and work out effective solution approaches

Fields of application: Plants and process engineering, thermal engineering, plastics processing, fittings, domestic engineering, power plants, solar technology, air conditioning and ventilation technology, fire protection, building design, wind load, pollutant dispersion and many more.

Research & Development

With clever simulation concepts to profitable innovations

Through the continuous and targeted use of CFD flow simulation, we deepen the company-specific product or process know-how, build up simulation knowledge and significantly accelerate the development processes. Time-consuming measurement procedures, lengthy prototype series and expensive faulty designs are a thing of the past. We think our way into development and innovation processes and support the emergence of new designs, functionalities and protectable inventions. For in-house or joint research projects, we stand by as a competent partner with our ideas and know-how.

Consulting & innovative ideas

A secure strategy for sustainable innovative strength

The strategic integration of numerical flow simulation into the company ensures cost and planning security in the value chain that everyone can rely on. We analyze the fluidic processes in the company and identify the innovation potential through the use of CFD flow simulation. We develop a coherent concept with measures and cost-benefit ratios and support the implementation of CFD technology in the company's internal processes.

Projects

Energy-efficient product design

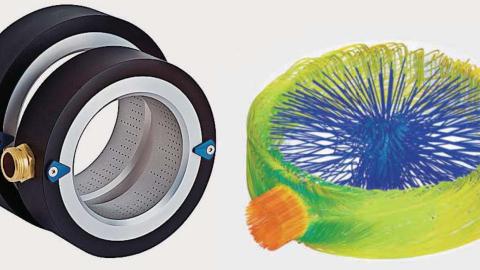

Increasing the efficiency of heat exchangers

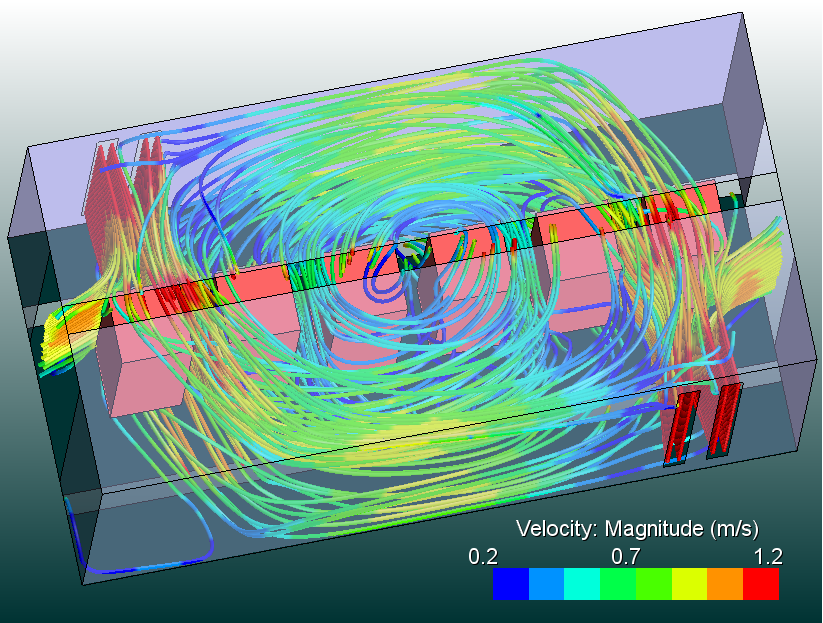

The gas flow of a shell-and-tube heat exchanger was investigated by means of CFD flow simulation. The aim was to quantify the flow situation. Furthermore, sections of the intercooler were investigated separately in order to check the flow distribution and pressure drop individually. Various geometry modifications were then developed to optimize the performance efficiency of the cooler.

Efficiency for Architecture & Building Technology

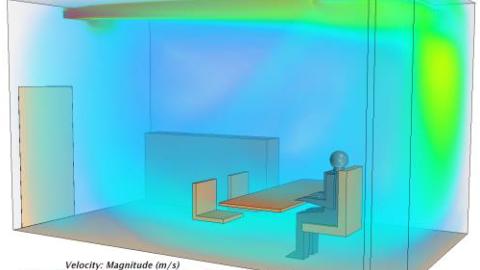

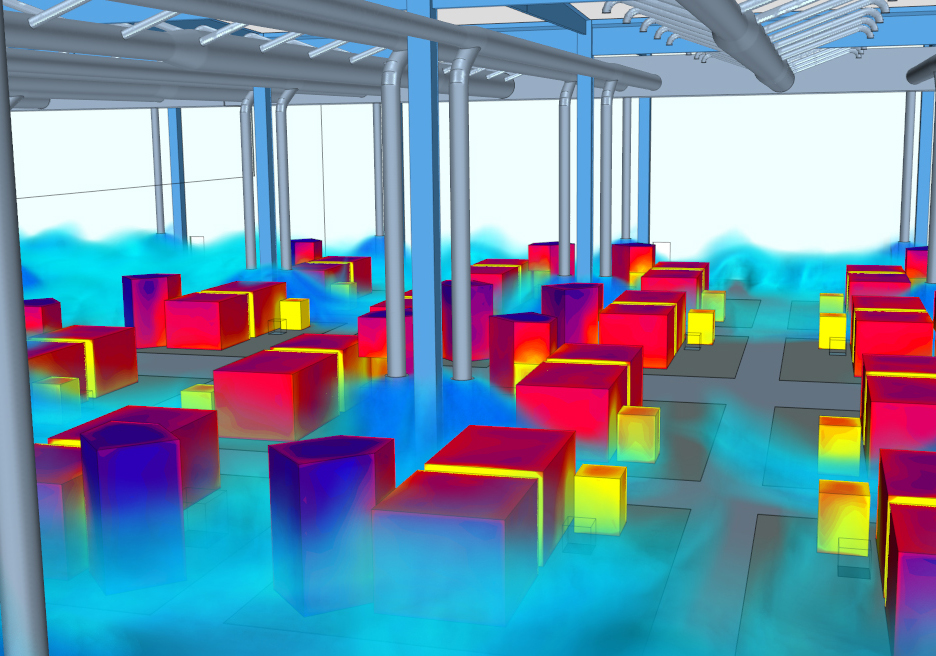

Efficient ventilation for production facilities

During the construction of a new foundry hall, a hall ventilation system was planned to ensure good and clean air quality. To ensure the functioning and energy efficiency of the planned ventilation concept in advance, flow simulation was used to investigate how the flows in the hall, consisting of supply air, exhaust air and the additional thermal convection caused by furnaces and castings, behave. The investigation resulted in concept optimizations: By optimally positioning the exhaust points, ventilation components were saved, resulting in lower investment costs and later in energy cost savings during operation.

Optimization of plants and processes

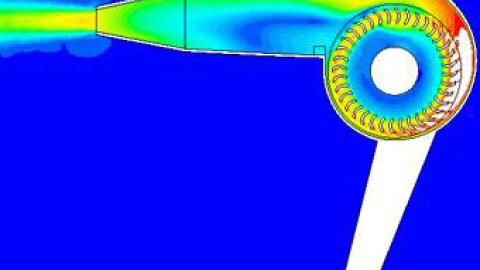

Efficient plants and plant components

To optimize the extraction system in a paint booth, CFD simulation provides a view of the overall situation in the booth and delivers all relevant physical variables: flow and paint particle distributions as well as velocity and pressure values. From these results, new insights into the efficiency of the extraction system are derived and weak points or potential savings in material use and energy consumption are revealed. Other important issues that can be investigated in surface treatment plants and processes are: uniform paint application, energy-saving drying, and the optimization of components such as spray nozzles and filters

Markets

Contact

HTCO GmbH

HTCO GmbH

Rabenkopfstraße 4

79102 Freiburg

Germany

HTCO GmbH is responsible for the content of this company profile as well as the compliance with the copyrights of the image material.